HighFire Energy Services has successfully cleaned tanks and vessels through out Alberta including large diameter crude oil tanks, condensate bullets, rail cars, Dehydration towers and wastewater tanks.

CLEANING TECHNOLOGIES

Vapor Phase Injectable Solvents

Using Steam as the solvent carrier allows us to apply an equal and fully distributed dose of solvent to every internal aspect of vessels, tanks and lines. In addition to that this cleaning method ensures that even the pore later of the material has been cleaned. This method of vessel cleaning is typically used on spheres, bullets towers and tanks where access would be limited using conventional methods. In addition to that, the high temperature steam ensures any light ends hydrocarbons are flashed and flared. This method is deployed to ensure LEL and H2S free prior to vessel entry.

Gamma Jet

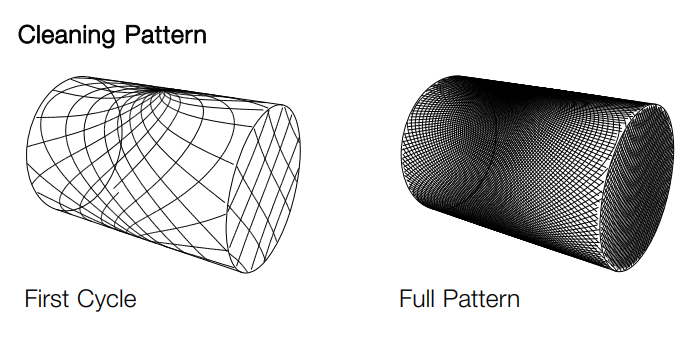

Using high pressure water and /or solvent the gamma jet provides excellent cleaning ability. While water is being injected through the nozzles at medium high pressure (250 PSIG) the head is slowly rotating ensuring 100% coverage of the vessel walls. Typically we use gamma jets systems where sludge, material and solids have developed on the walls and floor.

EXPERIENCE

• Turnaround Decontamination (LEL & H2S Free)

• Tanks, Vessels, Towers, Bullets and pipeline cleaning

• Heat Exchangers, Rail cars and more